Carbide inserts and tools manufacturing service providers play a crucial role in modern machining and manufacturing industries. These companies specialize in producing high-precision cutting tools made from tungsten carbide, a material renowned for its exceptional hardness and wear resistance. Carbide inserts are essential components used in various metalworking operations such as turning, milling, drilling, and threading. Their durability and ability to maintain sharp edges under extreme conditions make them indispensable for achieving superior surface finishes and extended tool life.

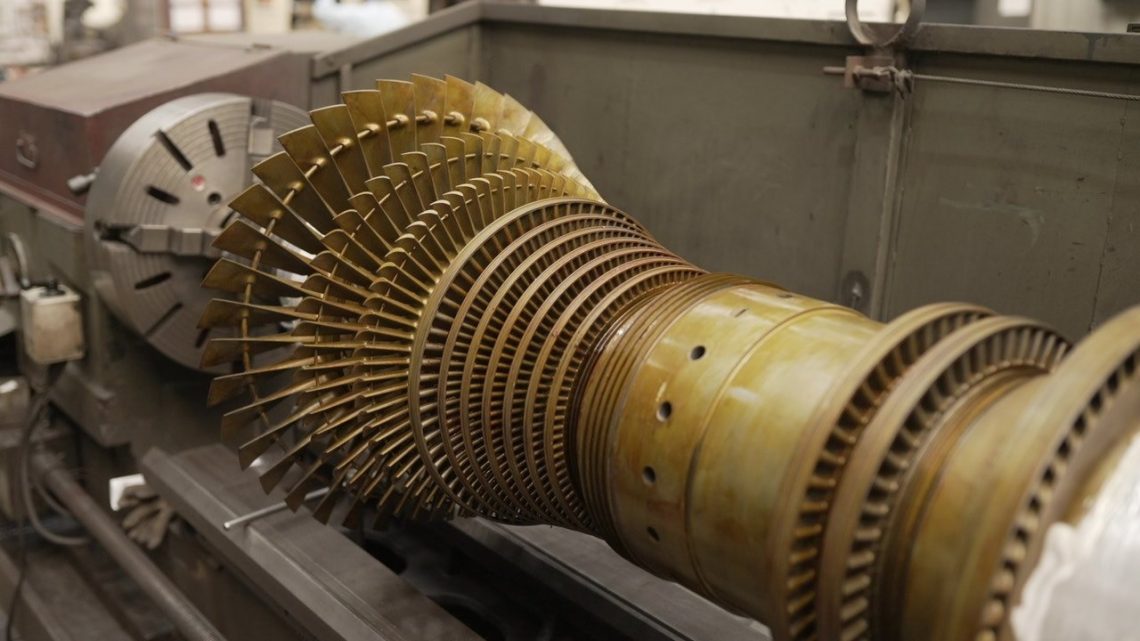

The manufacturing process of carbide inserts involves several intricate steps that require advanced technology and skilled craftsmanship. Initially, raw tungsten carbide powder is mixed with a binder material, typically cobalt, to create a composite that can be shaped through pressing or extrusion methods. This mixture is then subjected to sintering at high temperatures to fuse the particles into a solid form with enhanced mechanical properties. After sintering, the inserts undergo precision grinding to achieve exact dimensions and geometry tailored for specific machining applications. Coating technologies such as chemical vapor deposition (CVD) or physical vapor deposition (PVD) are often applied afterward to improve wear resistance further and reduce friction during cutting.

Service providers offering tungsten carbide manufacturer Latrobe inserts and tools manufacturing not only supply standard products but also customize solutions based on client requirements. Customization may involve adjusting insert shapes, sizes, chip breaker designs, or coatings suited for particular materials like stainless steel, cast iron, or aluminum alloys. By collaborating closely with customers’ engineering teams, these manufacturers ensure optimal tool performance that enhances productivity while minimizing downtime caused by frequent tool changes.

Quality assurance is paramount in this industry due to the critical nature of cutting tools in production processes. Leading manufacturers implement rigorous inspection protocols using coordinate measuring machines (CMM), optical comparators, and other metrology instruments to verify dimensional accuracy and surface integrity before delivery. Consistency across batches ensures reliable performance during demanding machining tasks.

In addition to production capabilities, many carbide insert manufacturers provide technical support services such as application consulting and troubleshooting assistance. They help clients select appropriate tooling solutions based on workpiece characteristics and machine parameters which contributes significantly toward cost efficiency in manufacturing operations.

Overall, partnering with a reputable carbide inserts and tools manufacturing service provider enables businesses to access high-quality cutting solutions tailored precisely for their needs. This collaboration fosters improved operational efficiency while maintaining competitive advantages through innovation in tooling technology advancements that meet evolving industrial demands effectively without compromising quality standards expected by end-users worldwide.

Extramet Products

2890 Ligonier St, Latrobe, Pennsylvania 15650

724-532-3041